- Electronic circuit maker how to#

- Electronic circuit maker professional#

- Electronic circuit maker free#

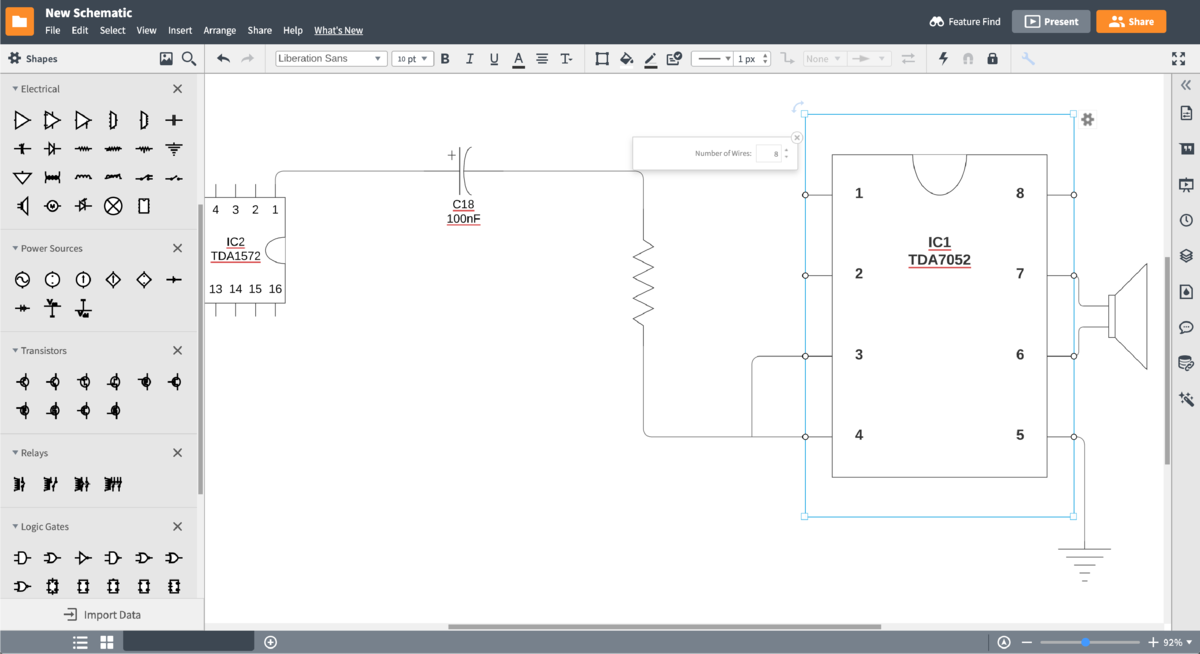

In the typical PCB design process, the basic circuit is already designed. Basic PCB Design FlowĪ very important part of PCB design is when the PCB design tools become relevant in a project. Occasional glimpses into other tools may be provided in the future lessons.

Electronic circuit maker free#

Of course, you are free to use whatever program you would like, though note that there may be important differences in tool workflow. We suggest using this tool if you would like to follow along with the "hands on" aspect. In this online HOPE series, we will be using KiCAD, a free, open source PCB ECAD. This is by no means an exhaustive list, but just a small sampling of avaliable tools. There are even integrated Mechanical CAD and PCB ECAD tools, such as

Electronic circuit maker professional#

To expensive industry professional tools: Thankfully, these days there exists many ECAD (Electronic Computer Aided Design) tools for designing PCBs, ranging from completely free (some even completely online!): More details will come in the future dedicated to PCB manufacturing details.īack before computers were commonplace, PCBs often were designed by hand, and every step of the process had to be verified manually. The fiberglass part provides stiff structure, while the copper provides the electrical connectivity.

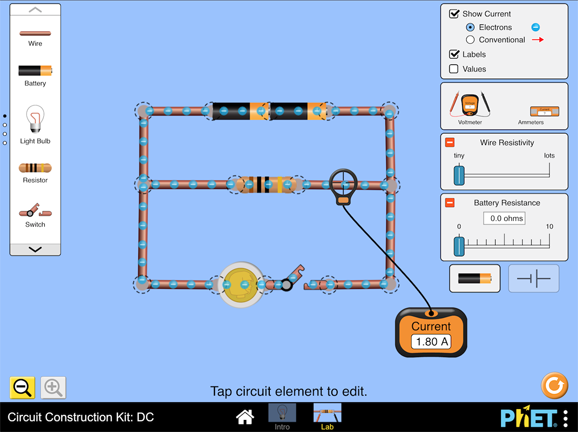

TL DR answer: A PCB is a copper and fiberglass sandwich. And what better option than their mother's breadboard? Drill some holes, add metal strips for power terminals, and you'd have a great foundation to work on. You've probably been introduced to electronics with the infamous white plastic breadboard:ĭo you know why they are called "breadboards"? Well, back before these nice little spring-hole breadboards became the defacto standard for electrical prototyping, hobbyists who wanted to build circuits would use a nice solid wooden board to hold their components and help them make the connections. Or perhaps you are in a bit of a rush and just need a single IC to work, so you attempt a deadbug: Sometimes, using a solid substrate to provide support for the connections is a good idea (wire wrap board): Behold, point-to-point wiring in an old-timey TV:

Back before the advent of the PCB, there was, well, just wires. Now, there are certainly ways to implement electronic circuits without PCBs. In this way it can keep things neat and tidy but also simple. The electrical connections between components are made inside of a stiff board the PCB also provides the connection pads for the components to be both mechanically and electrically attached to the board. In other words, a PCB is a kind of board that implements the connections and sometimes even components of an electrical circuit, as well as providing a fixed form and structure. The PCB, as its name implies, is a circuit board. Now, to properly answer the original question, we will answer the following, related question: What does a PCB do? More information about the manufacturing of PCBs will be covered later. why was this name chosen? Very simply: a PCB is a board that implements a circuit and was printed, somehow. The acronym PCB stands for: Printed Circuit Board.

Electronic circuit maker how to#

Learning how to make your own PCBs is an essential skill for electrical engineers, researchers, makers and of course, the college student looking forwards to joining the hardware team in one of their school's engineering project clubs.īasic understanding of electricity, electronic circuits, and their diagrams, as well as some experience working with actual electronic hardware.Ĭertainly a pertinent question for those looking to learn about how to make them. They can be found everywhere, from your phone to your rice cooker, your electric scooters to cars and buses and trains and possibly anything else you can think of. PCBs are an essential component in electronics. Why might you want to learn about PCB design?

0 kommentar(er)

0 kommentar(er)